Modern supply chains face increasing uncertainty, from geopolitical tensions to environmental disruptions and volatile demand patterns. Simulation models offer a powerful way to understand these dynamics and strengthen resilience across European industrial ecosystems. By recreating the behaviour of supply chains in a virtual environment, companies can test strategies, anticipate bottlenecks, and evaluate the impact of technologies long before real-world changes are implemented.

Why Simulation Models Strengthen Resilience

Simulation-based approaches support resilience in three essential ways:

- Anticipation of disruptions: Models can reproduce complex networks and test how they react to shocks such as delays, shortages, or capacity losses.

- Data-driven decision-making: By quantifying effects on inventory, production, service level, and cost, companies can identify the most effective mitigation strategies.

- Technology assessment: Simulations allow stakeholders to evaluate how digital tools, e.g., real-time monitoring, automation, predictive analytics, improve stability and performance under stress.

- Safe testing environment: Strategies can be tested without risk, enabling more informed investments and operational improvements.

What We Built: Models, Tools, and Ecosystems

To represent the diversity of European industry, four quantitative models were developed, each reflecting the structure, processes, and typical disruptions of a specific ecosystem:

Agri-Food Ecosystem – Wine Supply Chain (Discrete-Event Simulation)

Using the Order-to-Delivery Network (OTD) tool, a full end-to-end wine supply chain was modelled, including harvest cycles, fermentation, ageing, bottling, and distribution. Seasonal production dynamics and regional sourcing were incorporated.

Mobility Ecosystem – Electrified Automotive Supply Chain (Discrete-Event Simulation)

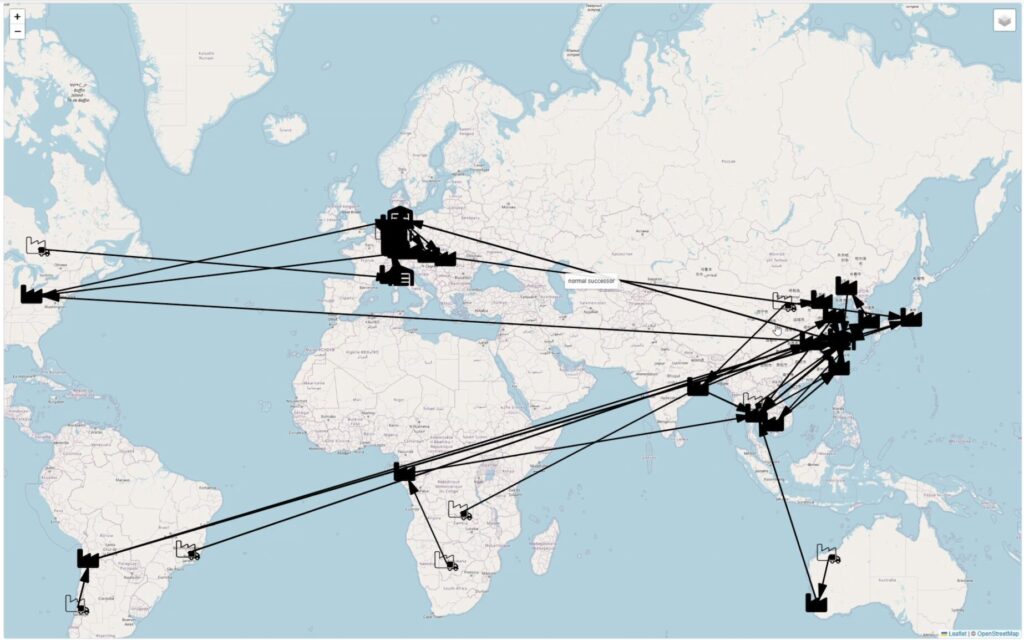

A highly interconnected EV supply chain was developed using OTD, capturing global raw material flows, European production clusters, and final assembly. Ports, transport legs, and multiple component suppliers were mapped in detail.

Textile Ecosystem – Shoe Manufacturing Supply Chain (Discrete-Event Simulation)

This model represents a multi-layered, SME-driven European shoe supply chain with many suppliers, intermediate materials, and regional production stages. OTD was used to simulate sourcing, manufacturing, warehousing, and distribution.

Digital Ecosystem – Mobility-as-a-Service (System Dynamics)

For the digital domain, a System Dynamics model was created to analyse the interaction of supply and demand in urban mobility services. The focus lies on digital platform performance, fleet availability, user adoption, and the technological influence on service quality.

First Insights and Findings

Across the four ecosystems, several key insights emerged:

- Baseline models are stable and validated: Each model successfully replicates typical operational behaviour, enabling reliable scenario testing.

- Critical disruption points become visible:

- Seasonal bottlenecks in agri-food (e.g., harvest concentration, ageing capacity).

- High dependency on global material flows in mobility.

- Vulnerable multi-tier supplier networks in textiles.

- Strong feedback loops between user demand and service capacity in digital MaaS.

- Technology shows clear potential:

Simulations indicate that digital tracking, automation, predictive forecasting, and improved coordination can significantly reduce delays, stabilise inventories, and enhance responsiveness. - Models are adaptable:

Each supply chain can be easily reconfigured for SME-specific cases, allowing tailored stress tests and technology assessments.

Together, these models provide a solid foundation for building more resilient, technology-enabled supply chains across Europe.

AUTHORS

Jakob Jacobsen

Fraunhofer IML

Jakob Jacobsen started as a research assistant at Fraunhofer after completing his Master of Science in mechanical engineering at the TU Dortmund. Here he is working in the field of supply chain management with a focus on the application of AI. In previous industry projects, he also had the opportunity to investigate the resilience of supply chain networks from a business analytics perspective.

Lucas Schreiber

Fraunhofer IML

Lucas Schreiber works as a Senior Scientist in the Supply Chain Engineering department at the Fraunhofer Institute for Material Flow and Logistics IML in Dortmund. He specializes in the simulation of supply chain management systems and employs simulation-based optimization techniques to enhance operational efficiency and resilience. His work includes industry applications and a leading role in the in the Gaia-X initiative, focusing on creating technology driven supply chain strategies that can adapt to changing market conditions.